Specifying Skylights: How to Choose Between Translucent and Transparent

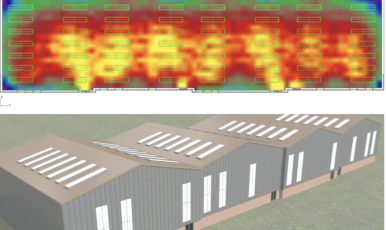

Skylights are a great, often economical way to introduce lighting into a space. Not only can you save on electric costs by utilizing skylights, but studies have shown that the introduction of natural daylight from skylights can increase retail sales by as much as 40%. This is because natural daylight can boost people’s mood and productivity.

But skylights are not one size fits all. Not only are there design options—ranging from a standard flat skylight to an eye-catching pyramid or geometric design—but before you can even choose a design, you must consider what material will best suit your skylights.

Material options include glass, acrylic, polycarbonate and fiberglass-reinforced polymer (FRP). Here are five qualities to consider when comparing these options.

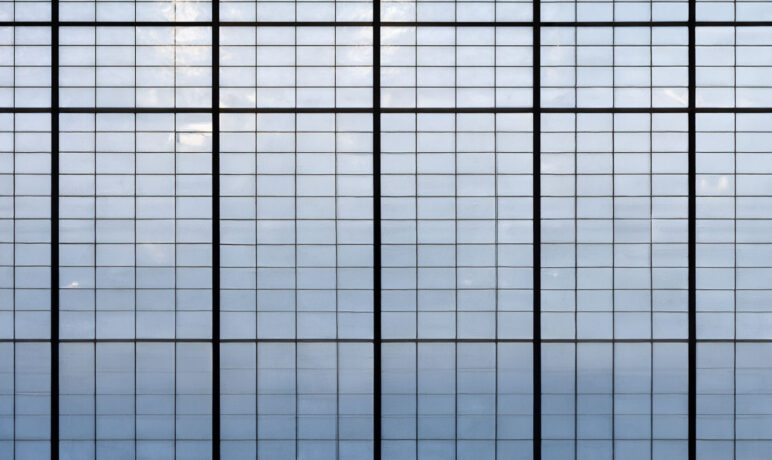

Quality of Light

Glass, Acrylic, Polycarbonate (Thermoplastic): These three materials are typically cast or extruded and transparent, meaning they are see-through and do not naturally control or filter light. Unfiltered sunlight entering a space can create problems with glare and become unusable light. When filters are added to these materials, they can lead to color distortion and alter the natural spectrum of light. Full-spectrum, diffuse light has the most health benefits, so despite often having higher visible light transmission values, transparent skylights do not provide the highest-quality light. Even multi-cavity polycarbonate—to which color is often added to give translucency—will redirect some light, but not eliminate glare. Fritted glass is another attempt to diffuse light but is only partially successful. Perfect diffusion, also known as Lambertian diffusion, cannot be achieved by these means.

FRP: FRP creates a translucent skylight with glass fibers that refract sunlight to diffuse full-spectrum natural light deep into a space. The diffusion of light prevents glare, allowing for comfortable, usable light.

Thermal Performance

Glass: Glass skylights have historically lacked thermal insulation, but today’s insulated glass units (IGUs) can achieve respectable insulation values. That being said, glass and aluminum systems still suffer from thermal bridging and can struggle with solar heat gain, ultimately creating inefficient pockets in your building envelope.

Acrylic, Polycarbonate: These thermoplastic materials offer the lowest thermal performance and also struggle with solar heat gain.

FRP: Kalwall’s translucent FRP sandwich panels offer the best of both worlds when it comes to daylighting and thermal performance. Translucent skylights can achieve U-values of up to .05 U or R-20, equal to that of a solid wall. They can also achieve solar heat gain coefficients as low as .04. Like the other skylight options, performance is customizable based on climate requirements, but no other skylight panel can match Kalwall’s thermal performance.

View

Glass, Acrylic, Polycarbonate: Transparent materials do allow for a view, but unlike windows in your façade, a skylight is not at eye level. The use of a skylight for view can be minimal.

FRP: Translucent skylights do not offer a view of the sky, but Kalwall’s skylights can be unitized with glass to provide the best of both worlds when a view is desired.

Structure

Glass: As the heaviest of these materials, glass requires significant structural support that can make installation time consuming and expensive. Glass is also susceptible to breakage and requires safety railings or other features to prevent fall-through.

Acrylic, Polycarbonate: Acrylic and polycarbonate skylights are lightweight and easier to install, but they are not structural glazing materials. They also require safety features to prevent fall-through.

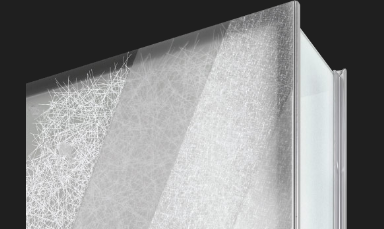

FRP: Kalwall’s FRP sandwich panels are structural and lightweight. They do not require significant support structure and are quick and easy to install. These translucent skylights are also man-safe, so skylights do not require safety railings or cages.

Maintenance

Glass, Acrylic, Polycarbonate: These materials are all cleanable, but when using transparent skylights, it is very visible when dirt and debris collect, requiring more frequent cleaning. Polycarbonate also scratches very easily, and acrylic is not impact resistant, meaning hail or other debris could cause damage.

FRP: With a translucent skylight, any debris that collects on the material is not visible from below. Kalwall’s FRP also has a self-cleaning surface, meaning normal rainfall helps to keep the exterior free of sediment. Today’s FRP face-sheet technology is also color stable and includes a permanent glass veil erosion barrier to eliminate fiber bloom.

Every project has different considerations. We encourage you to learn more about Kalwall’s translucent skylights.